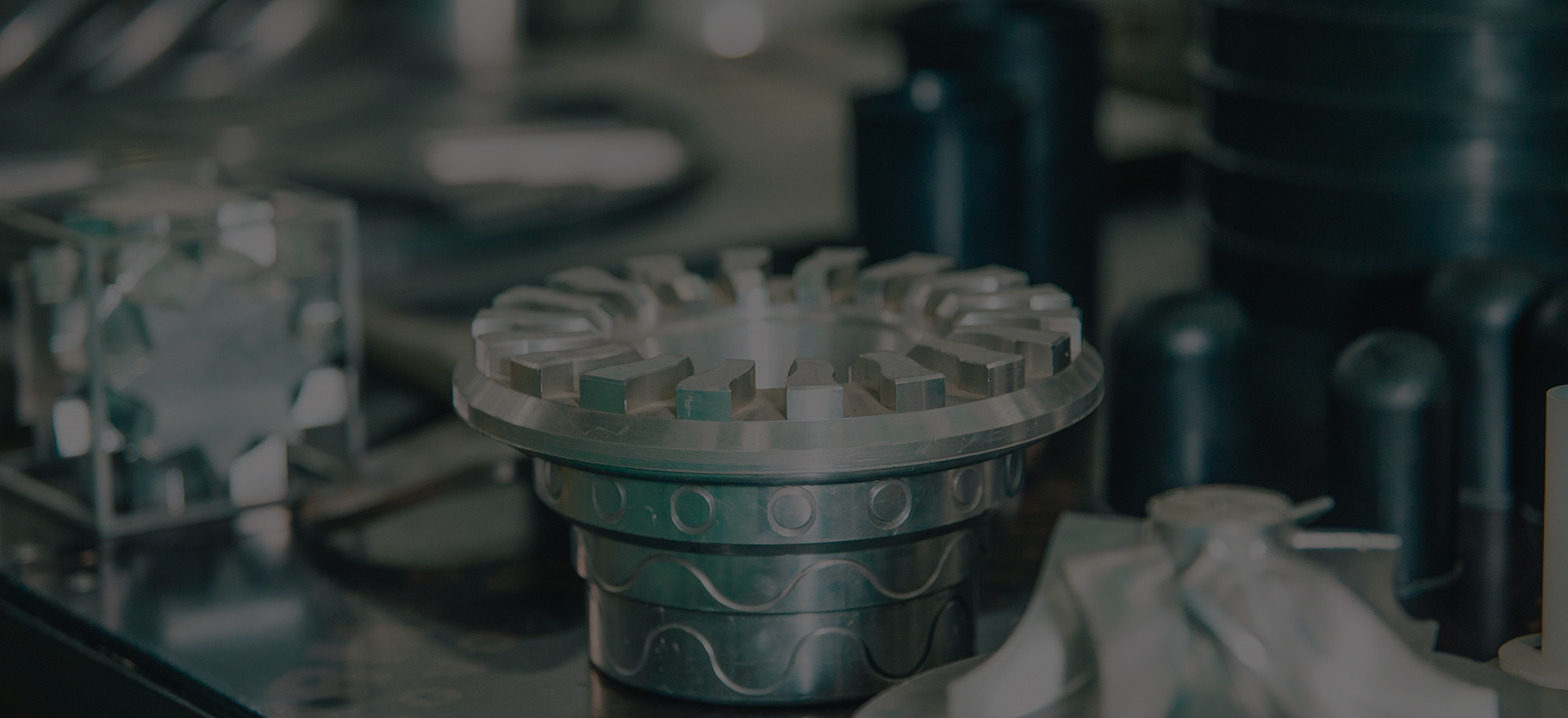

Plastic injection molding machinery plays a pivotal role in the manufacturing of plastic products across various industries. This advanced technology involves injecting molten plastic material into a mold, shaping it into the desired form, and allowing for the mass production of intricate and precise components.

The efficiency and precision offered by plastic injection molding machines make them indispensable in the production of items ranging from automotive parts and medical devices to consumer goods and packaging materials. The versatility of this machinery allows manufacturers to create complex designs and intricate details, meeting the ever-evolving demands of the market.

Key advantages of plastic injection molding machinery include high production speed, consistent quality, and cost-effectiveness in large-scale manufacturing. The ability to work with a wide range of plastic materials further enhances its applicability, ensuring the production of diverse products with varying properties.

As technological advancements continue to enhance the capabilities of plastic injection molding machinery, manufacturers benefit from increased automation, reduced waste, and the ability to create innovative designs. This machinery remains a cornerstone in the modern manufacturing landscape, contributing significantly to the production of high-quality plastic components that shape various aspects of our daily lives.